Why use a ball valve versus a plug valve?

In this article, BM Engineering Supplies looks at the individual merits of ball valves compared to plug valves.

Control valves are an essential component of any system where fluid flow must be monitored and manipulated. However, thorough knowledge of the process and the valve type, size and material is required to make the correct valve selection. Typically, valve selection boils down to what task it will carry out and in what space it will operate.

What are ball valves and how are they used?

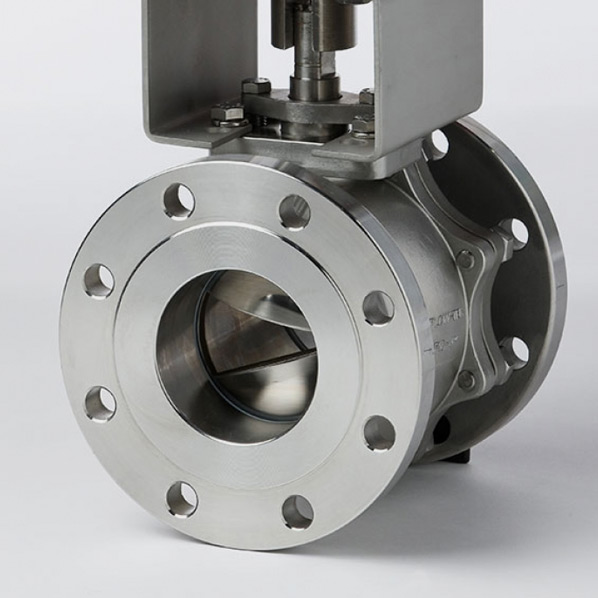

A ball valve is a valve with a spherical disc, which controls the flow through it. The sphere has a hole, or port, through its middle. This is where flow occurs, when that port is in line with both ends of the valve. When the hole is perpendicular to the ends of the valve the valve is closed and flow is therefore blocked. Ball valves are good for on/off situations, such as the emergency shut off for a sink.

There are four types of ball valves:

A full port or full bore ball valve has an over-sized ball, so that the hole in the ball is the same size as the pipeline, resulting in lower friction loss. Flow is unrestricted but the valve is larger and more expensive. This is only used where free flow is required, for example in pipelines requiring pigging.

In reduced port (or reduced bore) ball valves, flow through the valve is one pipe size smaller than the valve’s pipe size. This results in the flow area being smaller than pipe. As the flow discharge remains constant and is equal to the area of flow times velocity, the velocity increases with reduced area of flow.

A V-port ball valve has either a ‘v’ shaped ball or a ‘v’ shaped seat, allowing the orifice to be opened and closed in a more controlled manner – with a closer to linear flow characteristic. When the valve is in the closed position, and opening is commenced, the small end of the ‘v’ is opened first. This allows stable flow control. The design of V-port valves requires a more robust construction, due to higher velocities of fluids, which would quickly damage a standard valve.

A trunnion ball valve has a mechanically anchors the ball at the top and the bottom. This design is usually applied on larger and higher pressure valves (above 10 cm and 40 bars for example).

What are plug valves and how are they used?

Plug valves are valves with conically-tapered or cylindrical ‘plugs’. These can be rotated inside the valve body to control flow through the valve. Plugs in plug valves have one or more hollow passageways going sideways through the plug. This ensures that fluid can flow through the plug when the valve is open.

Plug valves are simple and, for that reason, generally economical. Of the two types of plug valves, one has a port through a cylindrical plug that is perpendicular to the pipe and rotates to allow the fluid to proceed through the valve if in an open configuration. In the other closed configuration the cylinder rotates about its axis, so the port is no longer open to the flow of fluid.

These types of valves are excellent for quick shutoff. The high friction resulting from the design, however, limits their use for accurate modulating/throttling.

Speak to one of BME’s knowledgeable advisers about your ball and plug valve requirements today by calling 0141 762 0657 or email sales@bmengineering.co.uk. For more information please visit www.bmengineering.co.uk.test.