What Is a Ball Valve? How It Works and the Different Types Explained

What Is a Ball Valve? How It Works and the Different Types Explained

What Is a Ball Valve? A ball valve is a versatile flow control device used across industries to regulate liquids and gases efficiently.

Understanding what a ball valve is and how it works is essential for anyone involved in fluid-control or process-industry systems. In this article, we’ll explain what a ball valve is, how a ball valve works, and provide a comprehensive breakdown of the different types of ball valves, so you’re equipped to choose the right valve for your application.

What Is a Ball Valve?

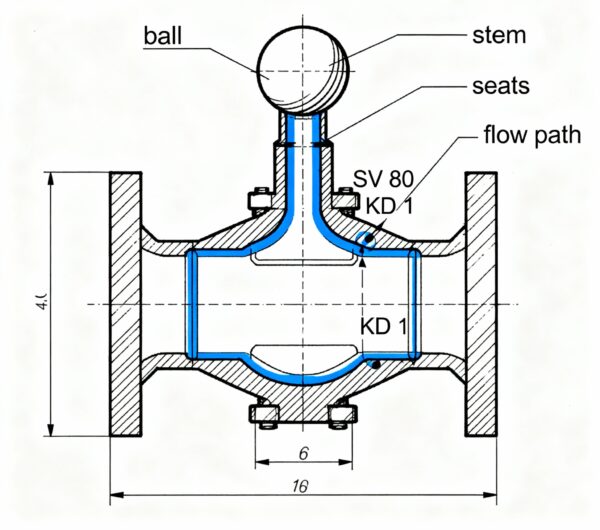

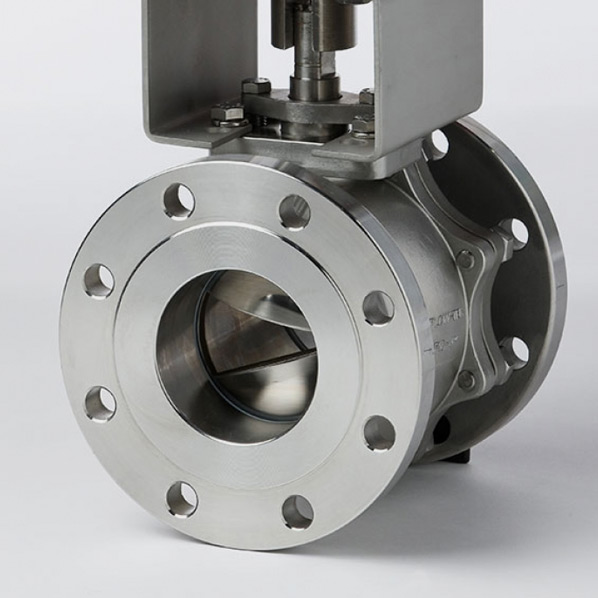

A ball valve is a type of quarter-turn valve that uses a spherical “ball” with a bore (hole) through it, inside a valve body. When the hole aligns with the flow, the fluid passes through; when the ball is rotated 90° (quarter turn), the flow is blocked.

- Quick on/off operation with minimal travel (90°)

- Good sealing capability and generally low leakage

- Versatile for both liquids and gases over a wide range of pressures and sizes

- Simple internal design leading to relatively low maintenance

How Does a Ball Valve Work?

A ball valve works by rotating the ball inside the valve body so that the bore (the hole in the ball) lines up or is turned perpendicular to the pipe flow.

- Open position: The ball’s bore aligns with the pipeline, allowing fluid to flow freely.

- Closed position: The ball is rotated so that the bore is perpendicular, blocking flow.

- Partial flow control: Some ball-valve types allow intermediate/controlled positions (throttling) through special designs.

The Different Types of Ball Valves Explained

1. Full-Port (Full-Bore) Ball Valve

- The bore diameter equals the internal diameter of the pipeline

- Minimises pressure drop, ideal for high-flow applications

- Common in pigging pipelines or critical flow systems

2. Reduced-Port (Standard-Port) Ball Valve

- Bore diameter is smaller than the pipe diameter

- Compact and cost-effective for general service

- A slight pressure drop is acceptable in most systems

3. V-Port Ball Valve

- V-shaped notch allows controlled, linear flow

- Precise throttling applications, handling viscous or abrasive fluids

- Common in chemical, water treatment, and process industries

4. Multi-Port Ball Valve (3-Way, 4-Way)

- Three or four ports allow flow diversion, mixing, or selection

- Used in complex piping systems requiring flexibility

- T-shaped or L-shaped bore configurations

5. Floating Ball Valve

- The ball is held in place by the upstream and downstream seats

- Ball shifts under pressure to create a tight seal

- Best for small to medium pressure systems; simple and cost-effective

6. Trunnion-Mounted Ball Valve

- The ball is fixed by trunnions; the seats move toward the ball to seal

- Ideal for large-diameter, high-pressure systems

- Lower operating torque, suitable for actuated systems

7. Metal-Seated Ball Valve

- Metal seats withstand high temperature, abrasive or corrosive media

- Used in demanding industrial environments

8. Body Construction Variants (One-Piece, Two-Piece, Three-Piece, Welded)

- Body design affects maintenance, installation, and cost

- Three-piece valves allow easy removal without pipeline disruption

- Common in processing industries requiring service flexibility

9. Cavity-Filler Ball Valve

- Eliminates dead space between the ball and the body

- Essential for hygienic applications like food & beverage and pharmaceuticals

10. Actuated / Automated Ball Valve

- Operated with pneumatic, electric, or hydraulic actuators

- Used in automated or remote control systems for process efficiency

Why Knowing the Right Type Matters

- Proper flow performance (minimised pressure drop or correct throttling)

- Suitability for process conditions (pressure, temperature, media type)

- Ease of maintenance, longevity, and cost-effectiveness

- Applicable across industries like distilleries, dairy, brewing, food & beverage, pharmaceuticals, data centres, maritime & shipping, renewables (bioenergy)

Conclusion

In summary, when you ask “What is a Ball Valve?” the answer is a quarter-turn valve using a spherical closure element. Asking “How It Works” highlights the simple mechanism of rotating the ball to open or block flow. And when considering “the Different Types Explained”, this guide covers all major types – full-port, reduced-port, V-port, multi-port, floating, trunnion, metal-seated, cavity-filler, body variants, and actuated versions.

Choosing the right ball valve ensures reliable, efficient, and safe operation across multiple industries, from brewing to bioenergy systems.

Call to Action

Order Ball Valves from BM Engineering Supplies

From full-port to V-port and multi-port ball valves, BM Engineering supplies high-quality solutions for every application.

🛒 Browse our ball valve range here

📞 Contact us for expert advice

Stay Connected

Follow BM Engineering on LinkedIn

Watch product videos on YouTube