SOMAS CONTROL VALVES

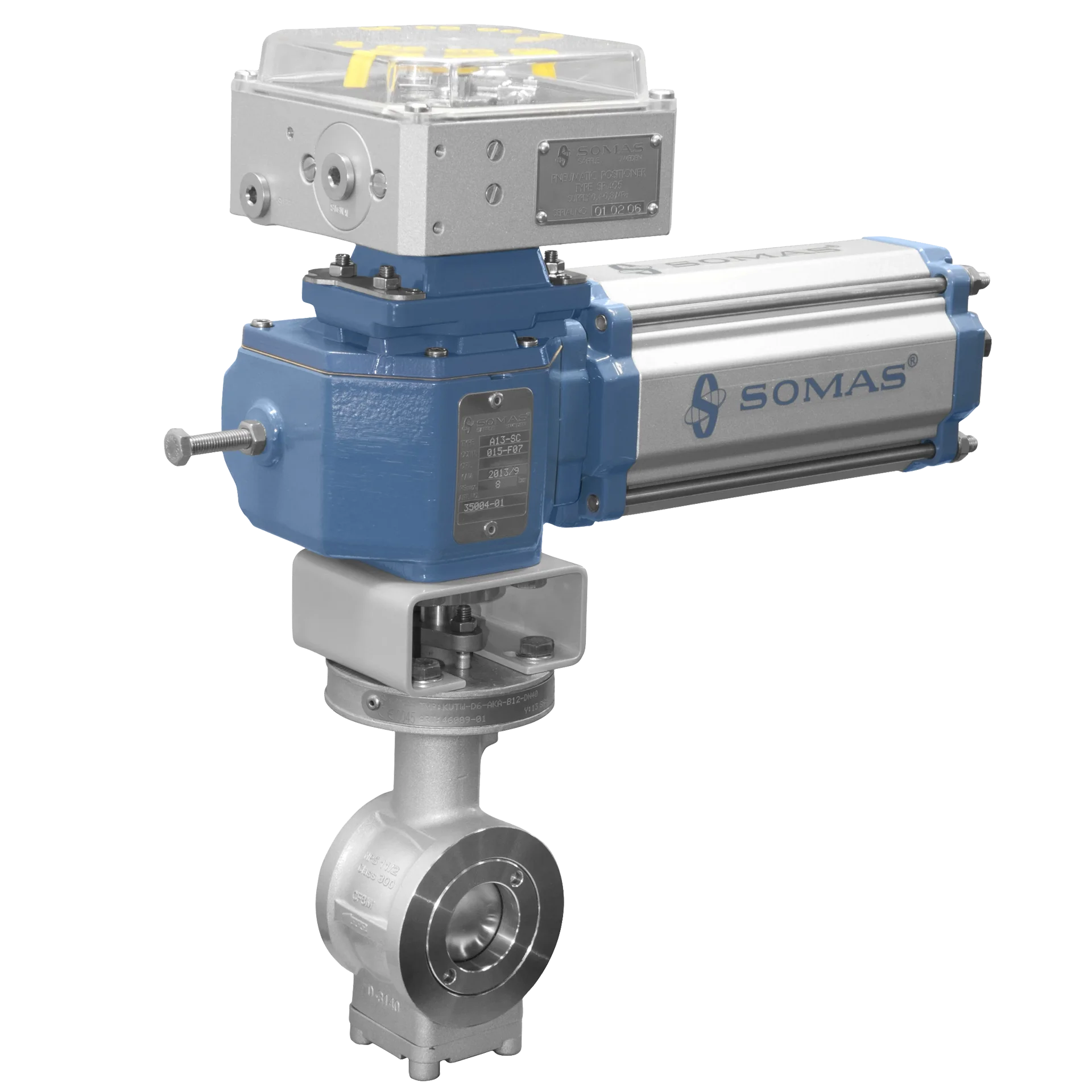

At BM Engineering Supplies, we are proud to supply a wide range of high-performance SOMAS control valves to industries across the UK. With a strong reputation for precision and durability, SOMAS valves are engineered in Sweden to deliver exceptional flow control performance in even the most demanding process environments.

Precision Flow Control from SOMAS

SOMAS control valves are designed to offer superior modulation and control across a wide variety of applications. Whether you’re handling steam, liquids, or gases, SOMAS valves deliver accurate, consistent regulation thanks to their innovative design and high-quality manufacturing. These valves are ideal for use in industries such as pulp and paper, chemical, pharmaceutical, food and beverage, and energy.

At BM Engineering, we supply the full range of SOMAS valve types, including:

-

SOMAS Ball Valves – For high capacity flow and tight shut-off in demanding conditions.

-

SOMAS Butterfly Valves – For compact, lightweight solutions with excellent control characteristics.

- SOMAS Ball Segment Valves – For high-capacity flow and precise control with tight shut-off.

Why Choose SOMAS Valves?

SOMAS valves are built from acid-proof stainless steel to ensure long service life and corrosion resistance. Their modular design also allows for easy maintenance and interchangeability of parts. With decades of experience in control valve design, SOMAS delivers solutions that meet the highest standards of quality, reliability, and efficiency.

Key features of SOMAS control valves include:

-

Excellent control characteristics with high rangeability

-

Robust construction with stainless steel as standard

-

Easy integration with pneumatic or electric actuators

-

Wide variety of sizes and pressure classes

-

Low total cost of ownership

UK Supplier of SOMAS Control Valves

BM Engineering Supplies is an official UK distributor of SOMAS control valves. With expert knowledge and a commitment to customer service, our team is here to help you select the most suitable valve solution for your process requirements. We provide technical support, fast lead times, and reliable nationwide delivery.

Whether you’re looking for a new installation or a replacement valve, trust BM Engineering to supply high-quality SOMAS control valves backed by engineering expertise.

SOMAS Valves

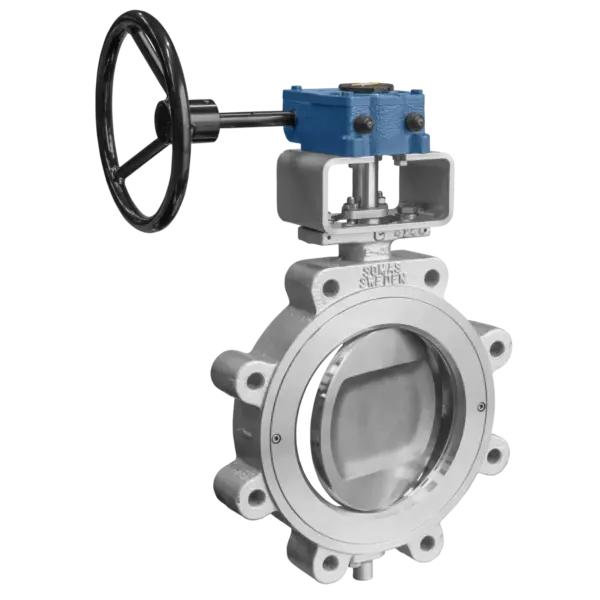

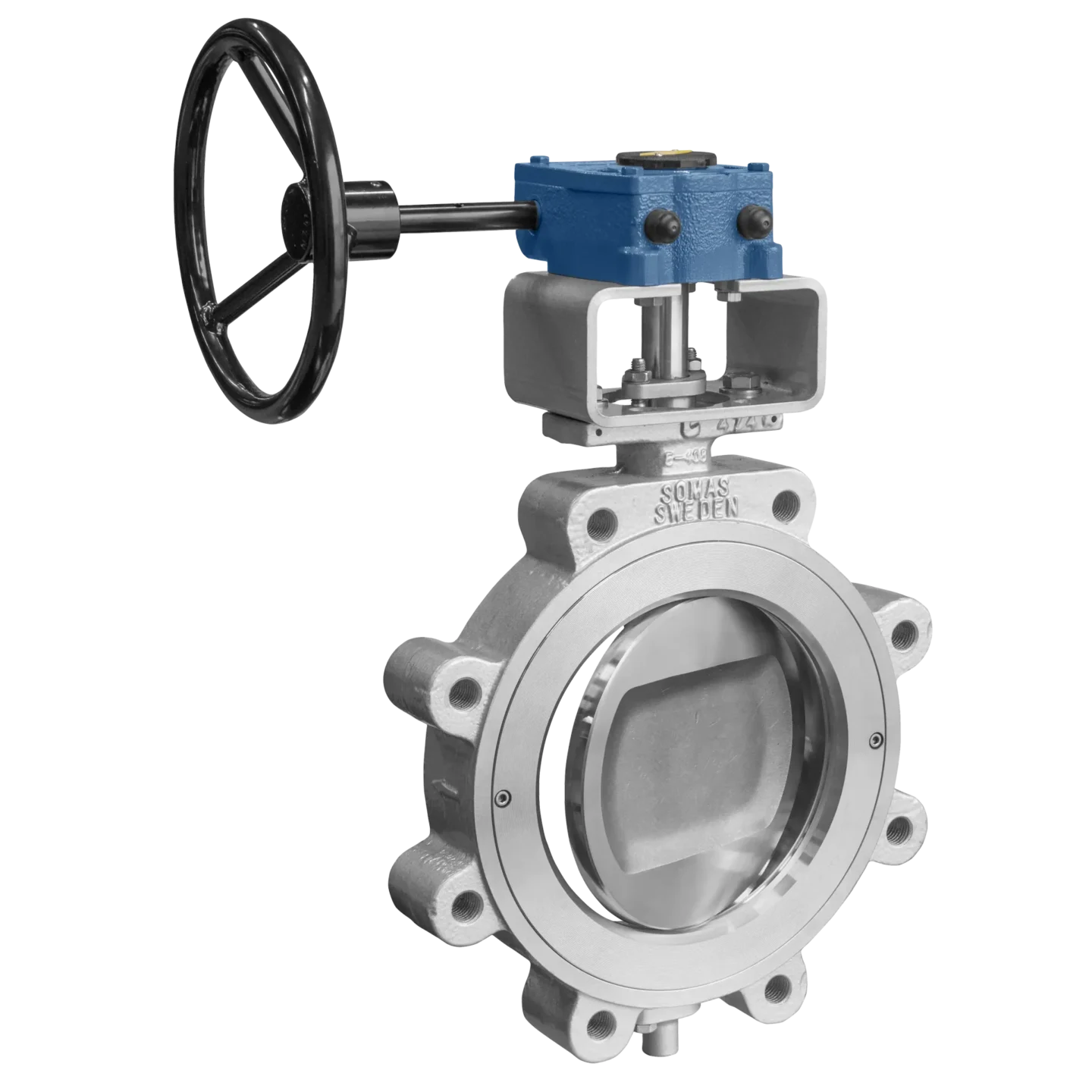

Butterfly valve – Lugged MTVL DN 80-DN 500

The MTV valves in the lugged version (MTVL) are specifically engineered to manage a diverse array of liquids, gases, and steam. These valves are capable of operating effectively within a wide temperature range, ensuring reliability and performance in various industrial applications. Their robust design allows for optimal flow control and pressure regulation, making them suitable for environments that demand versatility and durability. Whether used in chemical processing, water treatment, or steam generation, the MTVL valves provide a dependable solution for handling challenging media under varying conditions.

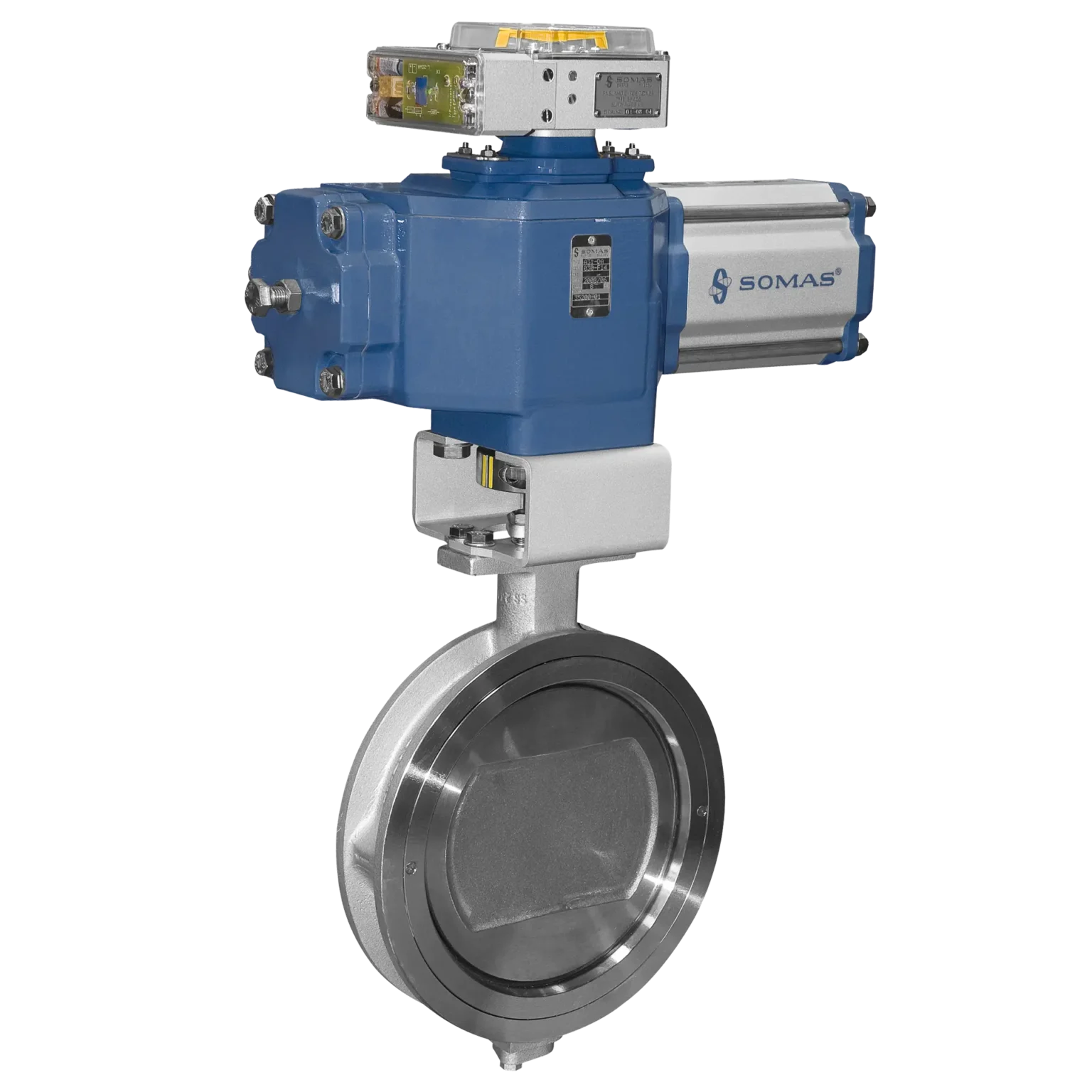

Butterfly valve – Wafer MTV DN 80-DN 500

The MTV valves in a wafer design consist of control, on/off, and shut-off valves, each serving a distinct purpose in fluid management. These valves are engineered to accommodate a diverse array of liquids, gases, and steam, making them versatile components in various applications. Additionally, they are constructed to operate efficiently across a wide temperature range, ensuring reliable performance in both high and low-temperature environments. The wafer design enhances their compatibility with different piping systems, allowing for easy installation and maintenance.

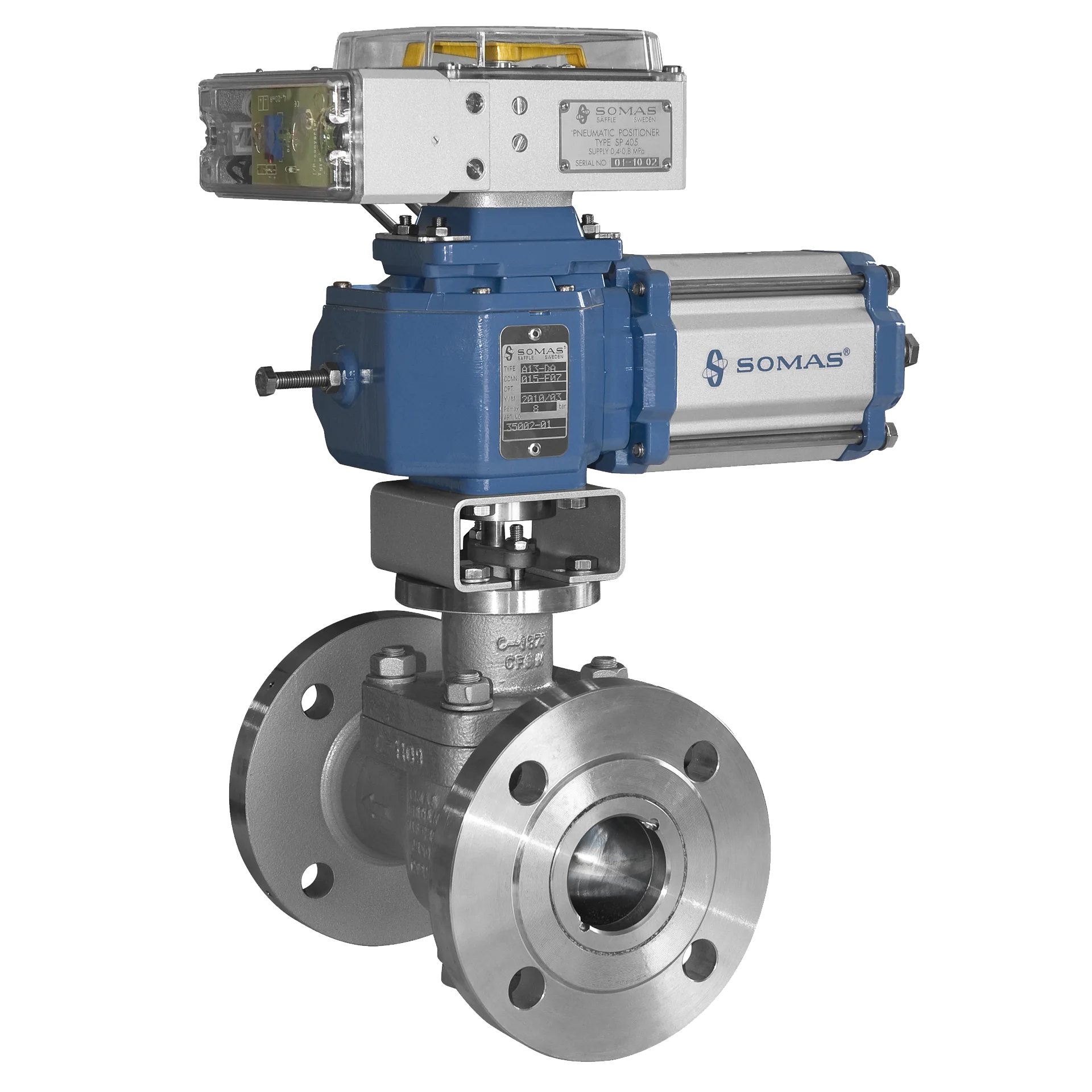

Ball segment valve – Flanged KVTF DN 25-DN 50

The valves are designed for both regulating and shutting off a wide variety of media, making them versatile tools in various applications. They can operate effectively within an extensive temperature range, ensuring reliability in different environments.

For applications involving liquids, contaminated media, or other similar substances, it is recommended to select type KVT/KVTF. This type is specifically engineered to handle impurities and ensure smooth operation.

If you are working with non-lubricating media, such as steam, gases, or corrosive acids, it is best to choose type KVX/KVXF. These valves are designed to withstand the unique challenges presented by these types of media, ensuring safe and efficient control.

By selecting the appropriate valve type, you can optimise performance and extend the overall lifespan of your system.

Ball segment valve – Wafer short KVTW DN 25-DN 250

The valve body is constructed as a single, unified piece, ensuring sturdiness and reliability in its performance. Somas has developed an innovative shaft device specifically engineered to facilitate efficient torque transmission. This design not only eliminates backlash, allowing for seamless operation, but also enhances accuracy in control, making it ideal for applications that require precision in valve management.