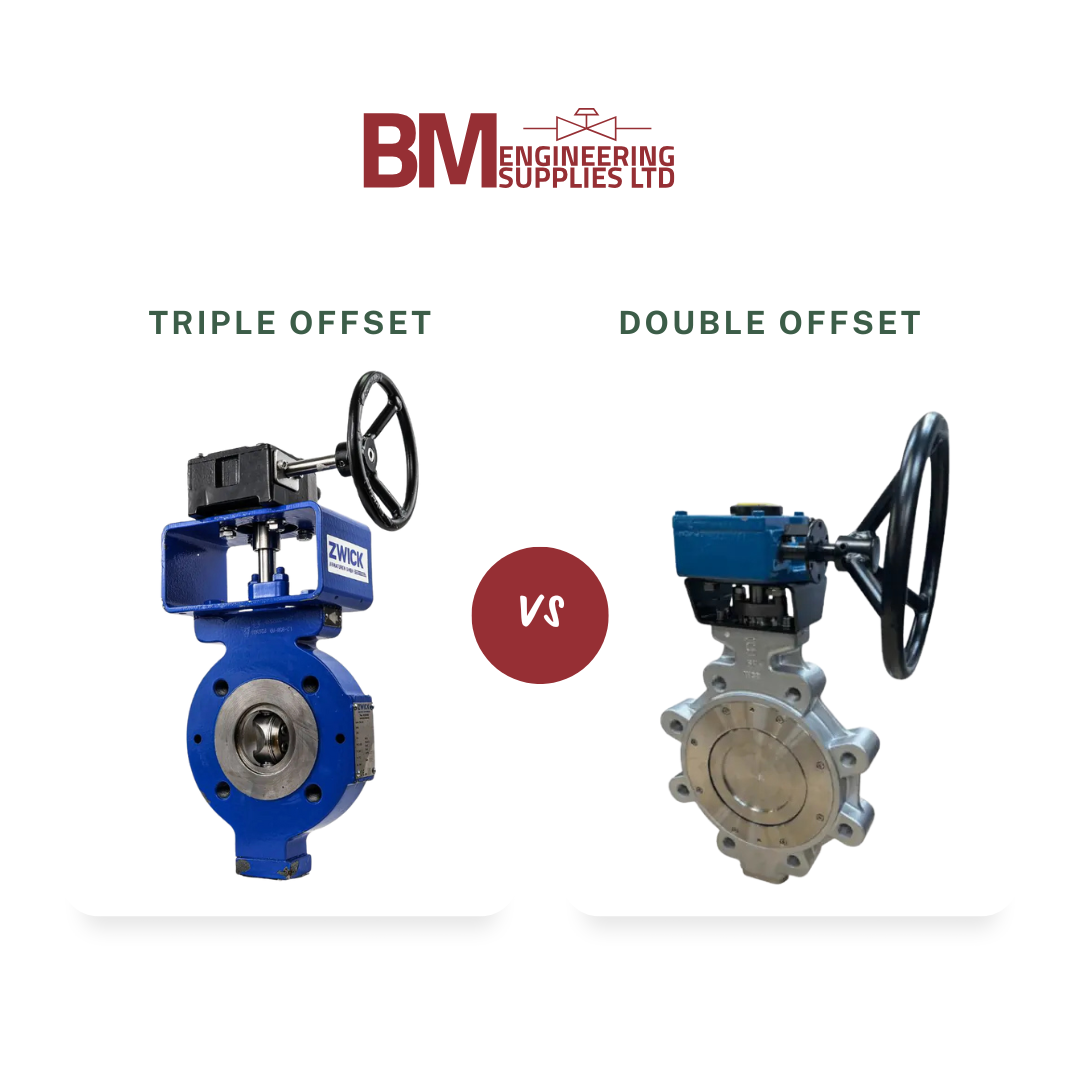

What are the differences between double offset and triple offset butterfly valves?

Double vs Triple Offset Butterfly Valves: What’s the Difference?

Butterfly valves have evolved significantly over the last 50 years, becoming one of the most reliable and space-saving valve types for controlling large flow volumes. While they serve a similar purpose to gate valves, butterfly valves offer enhanced flow regulation in applications with limited space. Among the most advanced types are the double offset and triple offset butterfly valves, each offering unique performance benefits.

In this article, we explore the key differences between double and triple offset butterfly valves, when to use each, and why triple offset butterfly valves are preferred in more demanding environments.

What is a Double Offset Butterfly Valve?

A double offset butterfly valve is designed with two key offsets:

- The shaft is offset behind the valve disc.

- The shaft is offset to one side of the valve centreline.

This configuration creates a cam-like motion, reducing seat wear during the valve’s opening and closing cycles. Friction occurs only in the initial and final 10% of movement, making it ideal for moderate-pressure and temperature conditions.

At BM Engineering Supplies, our double offset butterfly valves typically feature:

- A metal disc for durability.

- A soft seat (e.g. PTFE or elastomer) to provide a tight seal and reduce wear.

These valves are reliable, cost-effective, and suitable for a wide range of general-purpose flow control applications.

What is a Triple Offset Butterfly Valve?

A triple offset butterfly valve includes the same two shaft offsets found in double offset designs, with the addition of a third offset:

- The sealing surfaces of the disc and seat are machined into an angled conical profile.

This third offset eliminates friction throughout the full operating cycle—except at the point of closure. The result is metal-to-metal sealing without wear, ensuring a fire-safe, pressure- and temperature-resistant performance.

We supply Zwick TRI-CON triple offset butterfly valves – engineered in Germany for the highest level of performance in demanding conditions.

These valves are ideal for:

- Steam lines

- High-pressure gases

- Abrasive or corrosive fluids

- High-temperature process environments

Comparison Table: Double Offset vs Triple Offset

| Feature | Double Offset | Triple Offset |

|---|---|---|

| Seat Material | Soft (PTFE/elastomer) | Metal |

| Seat Friction | Low | Very low |

| Seal Life | Long | Extremely long |

| Suitable Fluids | Clean liquids or gases | Clean, dirty, or abrasive media |

| Shut-off Capability | Bubble-tight | Bubble-tight |

| Applications | Process, on/off, throttling | Extreme pressure, high cycling, steam |

| Temperature Resistance | Moderate | High |

| Pressure Resistance | Moderate | High |

| Cost | Moderate | Higher |

Key Advantages of Triple Offset Butterfly Valves

The main advantage of triple offset butterfly valves lies in their metal-to-metal sealing design. This feature:

- Allows reliable sealing in high-pressure and high-temperature conditions.

- Reduces long-term wear and maintenance.

- Ensures fire-safe operation even with aggressive media.

At BM Engineering Supplies, we offer triple offset valves suitable for:

- Oil and Gas

- Petrochemical

- Power Generation

- Pulp and Paper

- Water and Wastewater

- Steam systems in Food and Beverage industries

Learn more about our triple offset valve offering:

👉 Zwick Triple Offset Butterfly Valves

Pneumatic Actuation for Butterfly Valves

Many butterfly valves, especially triple offset designs, benefit from automated actuation. We supply a wide range of actuators to suit your system:

- Max Air Pneumatic Actuators: Ideal for high-cycle, industrial applications.

- Festo Pneumatic Actuators: Known for precision and reliability in automation.

Pairing your butterfly valve with the right actuator ensures lower operating torque, greater control, and long-term performance.

Which Butterfly Valve Should You Choose?

The decision between double offset and triple offset butterfly valves depends on your system’s requirements:

- If your application involves clean media, moderate pressure, and temperatures, a double offset valve may be ideal.

- For harsh conditions, including steam, high temperatures, or abrasive media, choose a triple offset butterfly valve for maximum performance.

Speak to Our Engineers

Not sure which valve is best for your application? We’re here to help.

📞 Call us today on 0141 762 0657

📧 Or email sales@bmengineering.co.uk for technical support and recommendations.

Explore our full Butterfly Valve Range and find the right solution for your system.

Contact Us Today