High Performance Double Offset Wafer Butterfly Valve (Stainless Steel)

Stainless Steel High‑Performance Double Offset Butterfly – Wafer Type

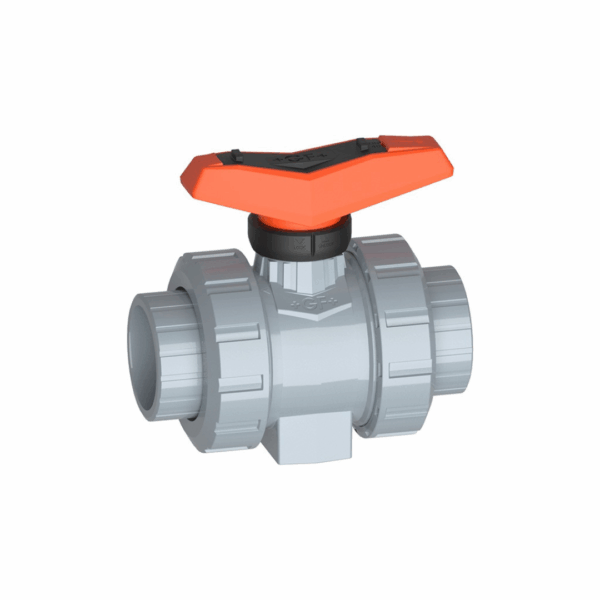

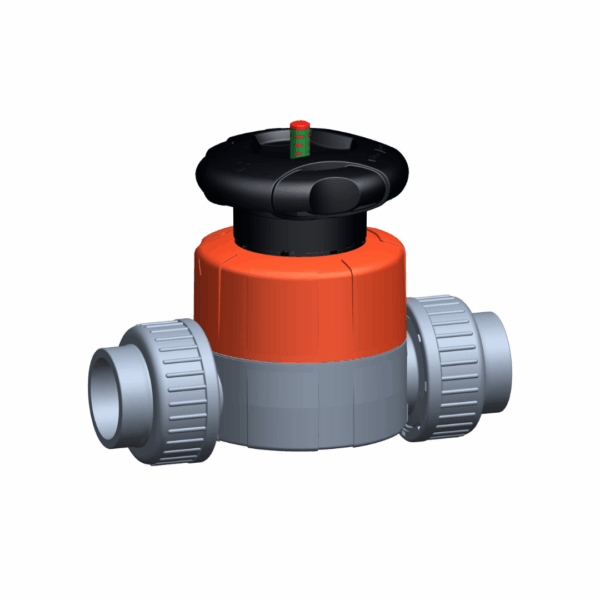

The Stainless Steel High‑Performance Double Offset Butterfly from BM Engineering Supplies is engineered for reliability in demanding flow control applications. Featuring a double eccentric disc design, it minimises friction by lifting the disc off the seat during operation—reducing wear and ensuring tight shut-off.

Constructed from durable CF8M stainless steel, this wafer-pattern valve fits compactly between PN10/16/25 or ANSI 150 flanges. Its RPTFE primary seat, backed by an Inconel 625 secondary seat, provides firesafe protection in line with API 607 (6th Edition) standards, ensuring performance under extreme conditions.

Designed for pressure ratings up to PN25 (15 bar) and temperatures ranging from –60 °C to +230 °C, this double offset butterfly is suitable for use with manual levers, gearboxes, or full automation via an ISO 5211 actuator flange.

Key Features & Benefits

-

Double Offset Butterfly Design: Reduces seat wear and operating torque

-

Stainless Steel Body, Disc, and Shaft: Corrosion-resistant CF8M/316 construction

-

Firesafe Seat Arrangement: RPTFE main seat with Inconel 625 backup (API 607)

-

Pressure & Temp Range: Rated to PN25 / ANSI 150, –60 °C to +230 °C

-

Wafer Pattern Body: Lightweight, compact, and flange-compatible

-

Actuator Ready: ISO 5211 top flange for electric or pneumatic control

-

Manual Options: Lever (2″–5″) or gearbox (6″–12″) operation available

🛠 Typical Specs at a Glance

| Spec | Detail |

|---|---|

| Sizes | 2″–12″ (DN50–DN300) |

| Pressure Rating | PN 25 / ANSI 150 |

| Temp Range | −60 °C to +230 °C |

| Seats | RPTFE primary, Inconel 625 backup |

| Fire Rating | API 607 6th Edition |

| Body/Disc/Shaft | CF8M Stainless Steel |

| Operation | Manual lever or gearbox; actuator-ready |

Torque requirements range from ~24 Nm (2″) to ~850 Nm (12″) at 25 bar

🏭 Applications

Ideal for demanding industrial systems requiring robust, fire-safe valves, including:

-

Petrochemical and chemical processing

-

Oil & gas and marine industries

-

Water treatment and utilities

-

HVAC and power generation