Why choose a triple offset butterfly valve vs ball valve

Both butterfly valves and ball valves are used in flow control applications where they can be applied to shut off or allow flow, in some cases also enabling flow regulation. Both types of valve have evolved to work extremely well under specific environmental conditions and in certain applications. We take a look at the case for butterfly valve vs ball valve to provide a clearer idea of which might be right for your application.

How do butterfly valves work?

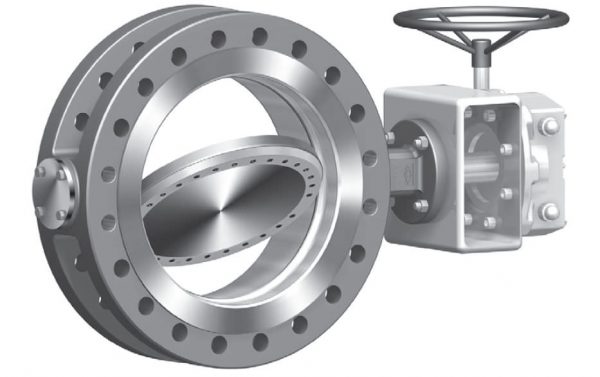

Butterfly valves are quarter-turn valves that use a disc positioned in the centre of a pipe to either allow or cut off the flow. Butterfly valves are lightweight and therefore need less support and are generally less expensive than other types of valve. However, there are a range of butterfly valves available, from the basic option (concentric) as described above to the triple offset butterfly valve design, which was developed specifically for use with harsh chemicals and in slurry or other dirty flow environments. They have a full, zero-leakage design that seals bubble-tight, their mechanism prevents clogging and the shut-off feature means an extended life. In a way, a concentric butterfly valve as compared to a triple offset butterfly valve design are very different solutions in themselves, let alone to compare to a ball valve.

How do ball valves work?

A ball valve uses a hollow pivoting ball to control flow through it. By rotating the ball within its housing you can vary the size of the aperture, and therefore the amount of flow. They are usually a quarter-turn valve, meaning that moving the actuator handle through 90 degrees will provide full flow. The valve control handle is usually set in line with the aperture of the ball allowing for quick visual confirmation of the valve’s state.

How to choose between a butterfly valve vs a ball valve

The main point of comparison is cost; ball valves are generally more expensive to manufacture and maintain than butterfly valves of the same capacity. Butterfly valves are also harder to operate in high pressure and flow situations and can be more prone to leakage. However, the triple offset butterfly valve design is better suited to slurries or liquids with solids in the flow, as the leading edge allows the cutting of potential obstructions. Ball valves are generally accepted to seal better than butterfly valves and don’t inhibit flow rates when fully open as the valve port can be the full diameter of the pipe.

When you look at butterfly valves vs ball valves, the critical thing to bear in mind is that although the ball valve may appear to be a better choice than the butterfly valve for more generalised applications, they are not intended for direct comparison. The triple offset butterfly valve design in particular was developed for use under very specific conditions. BM Engineering supplies offers a range of butterfly valves and ball valves carefully selected from industry-leading manufacturers. If you would like more information on selecting the right valve for your application, call us now on 0141 762 0657 or email sales@bmengineering.co.uk.