Ball Valves vs Gate Valves: Pros, Cons & Best Uses

Ball Valves vs Gate Valves: Pros, Cons & Best Uses

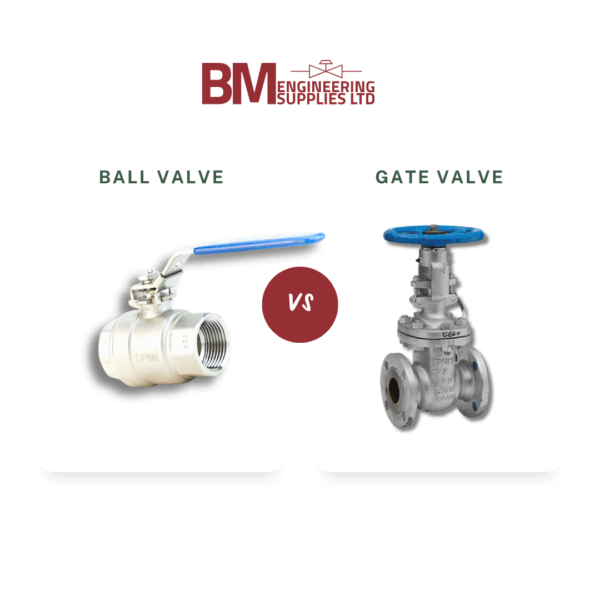

Choosing the right valve for your process can be critical. In this article, BM Engineering Supplies compares the key features, pros, and best uses of ball valves vs gate valves, helping you select the best fit for your specific needs.

Understanding Ball Valves vs Gate Valves

Both ball valves and gate valves are designed to isolate flow, but they achieve this in different ways. Each type brings unique advantages to the table depending on the process conditions, fluid type, and operational requirements.

What Is a Ball Valve and How Does It Work?

Ball valves use a spherical ball with a hole through the centre. When the handle is turned 90 degrees, the ball rotates to align the hole with the pipeline, allowing flow. Another turn blocks the flow completely.

Key Advantages of Ball Valves:

-

Quick operation with just a quarter-turn

-

Excellent sealing with a tight shut-off

-

Long service life even with frequent cycling

-

Minimal maintenance required

-

Compact design saves space

Ball valves are ideal for:

-

Gas and compressed air systems

-

High-pressure pipelines

-

Shut-off applications with minimal fluid loss

-

Steam, chemical, and petrochemical processes

However, ball valves are not ideal for throttling or flow regulation, as partial opening can cause erosion and reduced seal performance.

What Is a Gate Valve and How Does It Work?

Gate valves operate by raising or lowering a gate (usually a wedge or flat disc) to block or permit flow. They are multi-turn valves, typically operated via a threaded stem or gear actuator.

Key Advantages of Gate Valves:

-

Excellent for full, unrestricted flow — minimal pressure drop

-

Suitable for high-temperature and high-pressure systems

-

Effective in large diameter pipelines

-

Can handle slurries, viscous fluids, and thick liquids

-

Simple construction often leads to lower purchase cost

Gate valves are best used in:

-

Water and wastewater treatment plants

-

Oil and gas transmission lines

-

Marine and fire protection systems

-

Power generation and utility lines

-

Applications requiring infrequent operation, where throttling is not needed

Their slow operation reduces the risk of water hammer in systems sensitive to pressure surges.

Ball Valves vs Gate Valves: A Side-by-Side Comparison

| Feature | Ball Valves | Gate Valves |

|---|---|---|

| Operation | Quarter-turn | Multi-turn |

| Sealing | Tight shut-off | Moderate sealing |

| Flow Restriction | Slight | Minimal |

| Ideal For | Quick shut-off | Full flow in large pipelines |

| Maintenance | Low | Moderate |

| Durability | High | Moderate to high (when correctly maintained) |

| Cost | Slightly higher | Lower upfront cost |

| Throttling Capability | Not suitable | Not ideal, but better than the ball in some cases |

| Best Use | Clean gases, steam, and chemical processes | Slurry, wastewater, and fire safety systems |

Which Should You Choose: Ball Valves or Gate Valves?

When deciding between ball valves vs gate valves, consider the specific needs of your application:

-

Choose ball valves for systems that need fast shut-off, tight sealing, and frequent operation.

-

Choose gate valves when you require full-bore flow, are working with viscous or dirty media, or need a more economical solution for large-diameter piping.

Both valves perform excellently when used in the right context. The key is understanding the application, flow characteristics, and system pressures.

BM Engineering Supplies: Your Valve Experts

At BM Engineering Supplies, we supply a wide selection of ball valves and gate valves to suit a range of industries, including food and beverage, oil and gas, power, and water treatment. We offer:

-

Ball valves from ¼” to 6”, including two-piece, V-ball, steam-rated, and hygienic options

-

Gate valves in a wide range of sizes and materials, many available for next-day UK delivery

Speak to Our Experts

Still unsure which valve is right for you? Our experienced technical team is here to help you choose between ball valves vs gate valves for your application.

📞 Call us on 0141 762 0657

📧 Email sales@bmengineering.co.uk

🌐 Visit www.bmengineering.co.uk

at 0141 762 0657 or via email at sales@bmengieering.co.uk.