What is a Stream Trap & How do Stream Traps work?

In modern industrial steam systems, steam traps are essential components that ensure energy efficiency and operational safety. Whether you’re dealing with food processing, chemical production, or HVAC systems, managing steam and condensate effectively is critical. At BM Engineering Supplies, we specialise in supplying reliable steam traps that optimise performance and prevent costly energy losses.

What Is a Steam Trap?

A steam trap is an automatic valve designed to discharge condensate, air, and non-condensable gases from a steam system without allowing live steam to escape. This helps maintain thermal efficiency and keeps the system operating smoothly.

When properly selected and maintained, steam traps allow steam to deliver its full heat potential before being replaced by fresh steam, ensuring optimal energy use.

How Does a Steam Trap Work?

Steam traps operate by sensing temperature, pressure, or the density difference between steam and condensate. They open to remove condensate and close to retain steam.

The most basic traps work with minimal components — often a simple orifice at a low point in the system. However, industrial applications typically require more advanced solutions that automatically modulate to maintain performance and reduce energy waste.

In general, steam traps perform best when correctly sized for their application. While oversizing can still allow condensate removal, it may lead to premature wear, steam loss, or operational inefficiencies.

Common Types of Steam Traps

There are four main types of steam traps used across industrial systems:

1. Mechanical Steam Traps

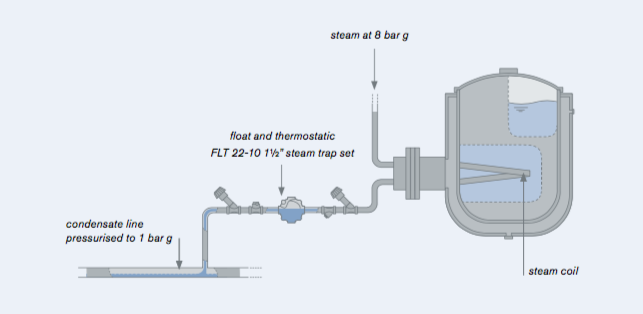

Mechanical traps use a float or inverted bucket mechanism to detect and remove condensate.

-

How they work: The float rises and falls with condensate levels, opening or closing a valve.

-

Pros: Reliable operation and quick discharge.

-

Typical lifespan: Around 3 years, depending on usage and maintenance.

2. Thermostatic Steam Traps

These temperature-sensitive traps open or close based on fluid temperature.

-

How they work: As condensate cools, the valve opens to discharge it.

-

Best for: Systems where some condensate cooling is acceptable.

-

Types include: Bimetallic and thermostatic bellows traps.

3. Thermodynamic (TD) Steam Traps

TD traps rely on the dynamic forces of steam versus condensate.

-

How they work: Steam pressure forces a disc against a valve seat. As steam condenses, pressure drops, and the trap opens.

-

Benefits: Compact and robust.

-

Limitations: Can suffer from air locking and wear due to constant cycling.

4. Venturi Nozzle Steam Traps

A modern and efficient solution using fluid dynamics to separate steam from condensate.

-

How they work: Condensate is throttled through a Venturi nozzle, keeping steam in the system.

-

Advantages: No moving parts, low maintenance, energy-efficient.

-

Ideal for: Systems with constant condensate load and high efficiency demands.

Choosing the Right Steam Trap

Selecting the right steam trap depends on:

-

System pressure and temperature

-

Type of steam application (process, heating, etc.)

-

Flow rates and load variation

-

Required maintenance intervals

Oversized steam traps may cause energy loss or process disruption, while undersized units risk flooding and heat transfer failure. Proper selection ensures longevity, energy savings, and reliable operation.

Steam Traps from Valsteam ADCA

BM Engineering Supplies is an official distributor of Valsteam ADCA, a globally respected manufacturer of steam system equipment.

Valsteam ADCA offers steam traps in various materials and configurations, including:

-

Sizes from DN15 to DN150

-

Pressures up to 80 bar

-

Flow capacities over 100,000 kg/h

Their product line covers everything from mechanical and thermostatic traps to advanced Venturi and thermodynamic models, engineered for durability and energy performance.

“An efficient steam trap defines the boundary between steam and condensate, enabling better system function and energy control,” says Valsteam ADCA.

Why Choose BM Engineering for Steam Trap Supply?

Since 1999, BM Engineering Supplies has supported process industries across Scotland and the UK with high-quality valve and steam solutions. With over 40 years of combined experience, we deliver trusted expertise in steam system design and component selection.

We supply:

-

Steam traps

-

Pressure-reducing valves

-

Steam control valves

-

Heat exchangers

-

Air eliminators

-

Steam injectors, and more

Get Expert Help with Your Steam Trap Selection

Our knowledgeable team can help specify the right steam trap for your application, ensuring optimal efficiency and longevity.

📞 Call us on 0141 762 0657

📧 Email: sales@bmengineering.co.uk

🔗 Visit: www.bmengineering.co.uk