Optimizing Pulp & Paper Production with Orbinox Knife Gate Valves

Optimising Pulp & Paper Production with Orbinox Knife Gate Valves

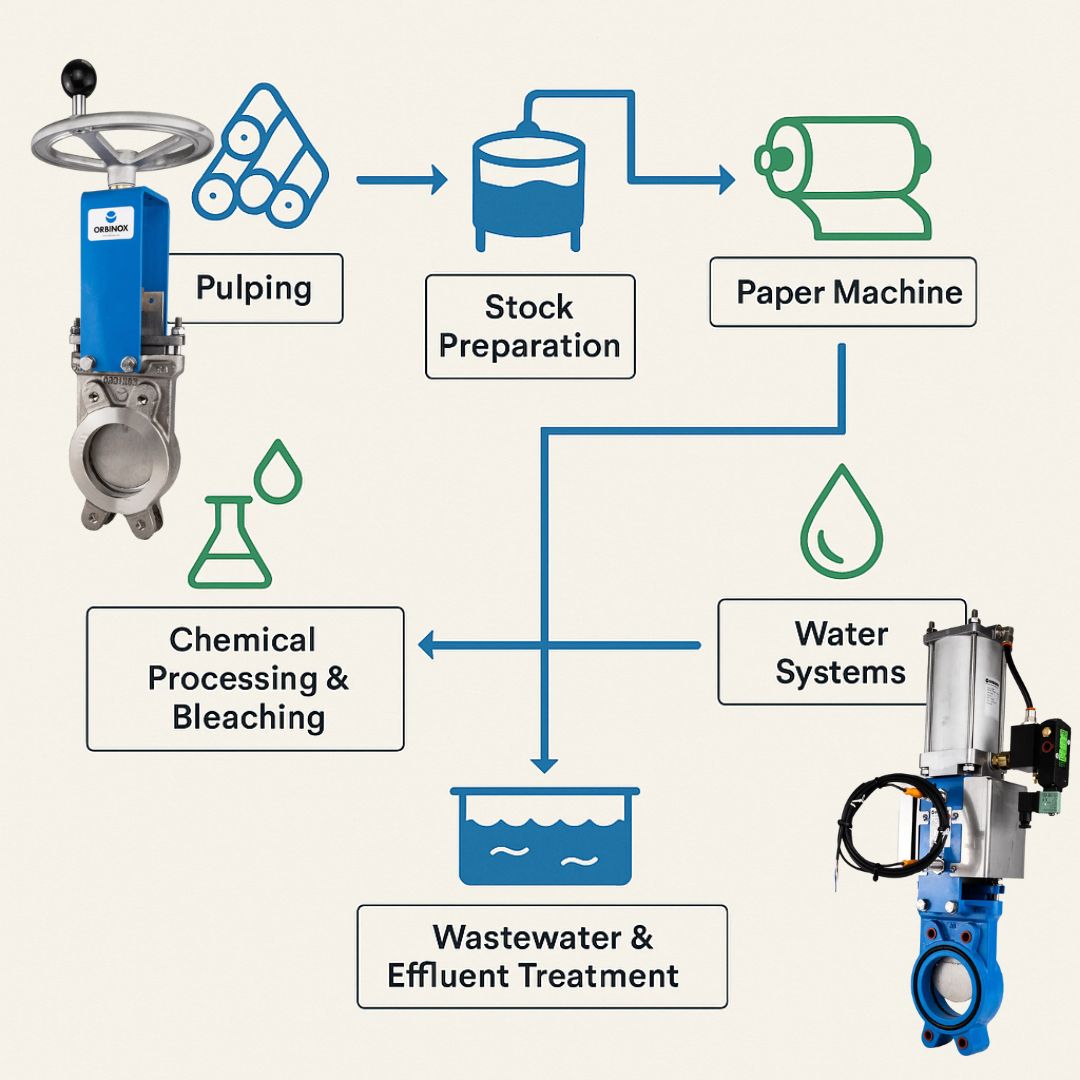

The pulp and paper industry relies on efficient flow control solutions to handle the challenges of processing raw materials, chemicals, and wastewater. From pulp slurries to wastewater treatment, selecting the right valves and automation solutions is crucial for improving efficiency and reducing downtime. At BM Engineering Supplies, we provide a comprehensive range of valve solutions, including the Orbinox knife gate valves, designed specifically for the strict demands of the pulp and paper sector.

Why the Orbinox Knife Gate Valves are Essential in Pulp & Paper Processing

Knife gate valves are widely used in the pulp and paper industry because they handle high-solid-content media, including pulp slurry, fibre-laden fluids, and wastewater. Unlike traditional valves that can clog or fail in these conditions, Orbinox knife gate valves are engineered to provide smooth operation, minimal maintenance, and long service life in harsh environments.

Key Benefits of Orbinox Knife Gate Valves

-

Designed for High-Solid Fluids – Prevents clogging and ensures reliable operation.

-

Uni– or Bi-directional Flow Control – Models available to suit pulp slurry and wastewater applications.

-

Corrosion-Resistant Materials – Available in stainless steel, duplex, and special coatings for aggressive chemicals.

-

Custom Automation Options – Pneumatic, electric, and hydraulic actuation for process efficiency.

Valve Applications Across the Pulp & Paper Process with Orbinox Knife Gate Valves

1. Pulping & Stock Preparation

Challenge: Handling thick pulp slurry and fibrous media in digesters, refiners, and stock preparation units.

Solution:

-

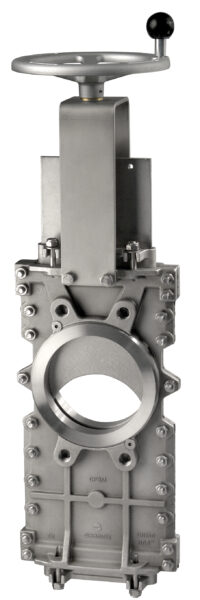

Orbinox EB Series Knife Gate Valve – Specifically designed for pulp, paper, and wastewater applications, featuring a full-bore design to prevent clogging and fibre build-up.

-

Orbinox TK Valve—This bi-directional through-conduit valve with a ported gate is ideal for high consistency stock (pulp with high fibre concentration). Its fully stainless steel construction and K-ring seat design enhance durability and ease of maintenance in fibrous and abrasive applications.

More info: TK ORBINOX

2. Chemical Processing & Bleaching

Challenge: Controlling aggressive chemicals like chlorine dioxide, sodium hydroxide, and hydrogen peroxide.

Solution:

-

Orbinox EX Series Knife Gate Valve— This valve is manufactured in corrosion-resistant stainless steel for chemical handling and is available with PTFE coatings for extra protection.

3. Paper Machine & Water Systems

Challenge: Managing steam, condensation, and water flow to ensure energy efficiency in drying and pressing sections.

Solution:

-

Orbinox BX Series – A robust stainless steel knife gate valve, ideal for water system regulation. (Note: For high-pressure steam, other valve types may be more appropriate.)

4. Wastewater & Effluent Treatment

Challenge: Handling sludge, fibrous wastewater, and chemical-laden effluents in treatment plants.

Solution:

-

Orbinox WB Series Knife Gate Valve – Designed for sludge and wastewater applications, with a full-flange design to handle high pressures and tough media.

5. General Applications in Hot & Humid Environments

Challenge: Prolonged exposure to moisture, heat, and fibre-rich media leads to corrosion and difficult maintenance.

Solution:

-

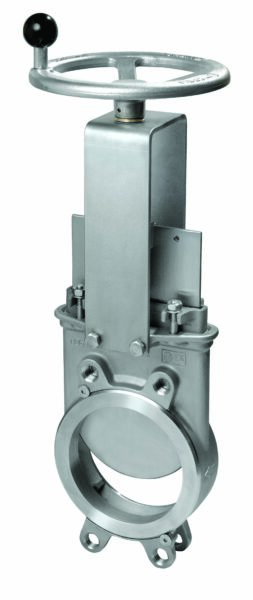

Orbinox EK Valve – A uni-directional stainless steel valve ideal for pulp and paper facilities where humidity and heat can degrade cast iron valves. It features the innovative K-ring seat retainer, which is easy to replace and extends the valve’s lifespan.

“Unique design that mechanically locks the seal in the internal of the valve body with a cast, easy-to-replace, stainless steel seat ring. Standard EPDM is also available in different materials such as PTFE, etc.”

More info: EK ORBINOX

Automated Valve Solutions for Maximum Efficiency

BM Engineering Supplies not only offers Orbinox manual knife gate valves but also provides automated valve solutions, including:

-

Pneumatic Actuators – Ensuring fast and reliable valve operation.

-

Fail-Safe Systems – Custom-engineered for plant safety and operational efficiency.

-

Positioners & Accessories – Enhancing process control and remote operation.

Partner with BM Engineering Supplies for Pulp & Paper Efficiency

With years of expertise in valve automation and supply, BM Engineering Supplies helps pulp and paper manufacturers optimise their processes with high-performance knife gate valves and automation solutions.

Contact us today to discuss your specific requirements and find the best Orbinox valve solutions for your facility!

Visit our online store at www.bmengineering.com/store

or contact BM Engineering Supplies today

at 0141 762 0657 or via email at sales@bmengieering.co.uk.