Where are knife gate valves used?

Knife gate valves were developed with very specific applications and industries in mind, namely for use with flowing media that contains solids. We take a look at where knife gate valves are used, how they work and which industries they are most suitable for.

What is a knife gate valve?

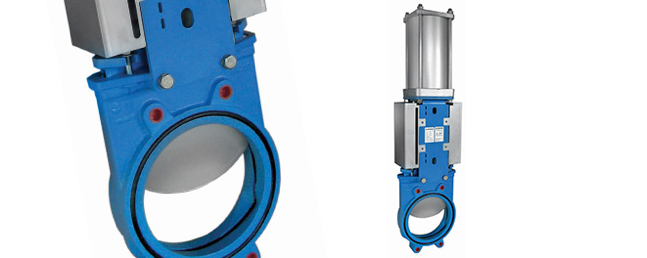

A knife gate valve is similar to a gate valve except that it has a sharpened leading edge to better cut through slurry or viscous media. The ‘gate’ part of the name derives from the fact that the valve opens by lifting a barrier – or gate – out of the path of the fluid to allow it to flow. Usually, a knife gate valve is operated using a stem which is connected to an actuator (often a hand wheel but sometimes via a pneumatic cylinder, hydraulic cylinder or electric actuator), and the gate is generally a sharpened disc. Knife gate valves are designed mainly for binary operation (where the valve is entirely opened or closed) and process isolation in systems with media that have a high concentration of suspended solids.

What applications are knife gate valves used for?

Knife gate valves are designed to be used in systems where the use of ordinary gate valves may be inhibited by solid matter in the process flow. The bladed edge of the disc is designed to cut through any solids in the aperture upon closing. This means that the common industries where knife gate valves are used would typically be within process systems in wastewater treatment plants, pulp and paper plants, chemical plants, mining and cement plants – any process in which thick, viscous fluids containing solids of some sort might be found.

Because of where knife gate valves are used, their design is primarily to support on-off services, and therefore it is not recommended that they are used for flow regulation. When fluid pushes against a partially closed gate, vibration occurs, which means that cavitation will eventually damage the seat and the body.

Why are knife gate valves better than alternative valve options?

Due to the disc and mechanism being external of the aperture when fully open, knife gate valves have a minimised pressure drop in flow compared to other valve types. They are easy to actuate thanks to the perpendicular nature of the disc, plus the sharpened leading edge makes them ideal for the industries where knife gates valves are used – those where suspended solids are found within the media flow. When compared to standard gate valves, they also have a relatively low weight and are therefore generally cost effective.

Knife gate valves from BM Engineering

When a valve is designed for such a specific application and environment, we know that the businesses working within those industries will expect the ideal solution, alongside the ultimate in quality and operational efficiency. BM Engineering offer a range of knife gate valves from Orbinox, the leader in the design and manufacture of these products. Orbinox began life working specifically with the paper industry – no other business understands knife gate valves quite like Orbinox do, nor is better placed to design them. If you have an application where knife gate valves are used and would like to speak to an expert, why not call BM Engineering and talk to one of our advisors on 0141 762 0657.