Solenoids for Refrigeration | Valve Guide for HVAC-R Systems

A Complete Guide to Solenoids for Refrigeration Systems

Solenoid valves play a vital role in many industrial applications, but they’re especially important in the HVAC-R industry, where precision and reliability are crucial. In refrigeration systems, solenoid valves control the flow of refrigerant throughout the cycle, enabling efficient operation and automatic control.

In this guide, we explain what solenoids for refrigeration do, how they work, how to size them correctly, and where to source trusted, high-quality options.

What Are Solenoids for Refrigeration?

A refrigeration solenoid valve is an electromechanical component that uses electrical energy to control the movement of gases or liquids, specifically refrigerants. These valves are used to start or stop refrigerant flow automatically based on system requirements. They eliminate the need for manual operation and help regulate cooling with consistent precision.

The most common function of a solenoid in refrigeration is to open or close the refrigerant line, depending on the system’s demand. This on/off control helps maintain ideal performance levels across various stages of the cooling cycle.

How Do Solenoid Valves Work in Refrigeration?

In larger cooling systems, solenoid valves are often installed in line with multi-cylinder compressors. They are triggered using the discharge pressure of the compressor to control refrigerant flow between system components.

When the system calls for cooling, the solenoid opens and allows refrigerant to pass through to the condenser. When no cooling is needed, the valve closes and redirects the refrigerant to the suction line. This simple action helps manage pressure, energy use, and system performance with minimal intervention.

Selecting the Right Refrigeration Solenoid Valve

When choosing or replacing a solenoid valve in a refrigeration system, several technical factors should be considered:

1. Operation Type

Solenoid valves are either:

Direct-operated – ideal for small systems and low flow rates.

Servo-assisted – better suited to larger systems with higher flow requirements. These need a minimum differential pressure to operate effectively.

2. Valve State

You can choose between:

Normally Closed (NC) – closed when de-energised; ideal for liquid lines to prevent refrigerant flow during power outages.

Normally Open (NO) – open when de-energised; suitable where closure is only occasionally required.

3. Material Compatibility

The valve body and internal components must be compatible with the refrigerant or fluid being controlled. Brass, stainless steel, and specially coated internals are common in refrigeration.

4. Compliance and Safety

Ensure the valve meets relevant safety standards such as:

ATEX (for explosive atmospheres)

PED (Pressure Equipment Directive)

How to Size Solenoids for Refrigeration Applications

Correctly sizing your solenoid valve ensures system efficiency and valve longevity. Consider the following:

Flow requirements: Choose a valve with the right port size for your system—typically 6mm to 10mm for direct-acting, larger for servo-assisted types.

Pressure range: Confirm the system’s working pressure and ensure it exceeds the valve’s minimum differential pressure.

System dynamics: Understand partial load behaviour, especially with servo-assisted models, to avoid failure in low-pressure conditions.

Incorrect sizing can lead to poor performance, short service life, or even system damage.

Where to Buy Solenoids for Refrigeration

BM Engineering Supplies provides a wide range of solenoids for refrigeration applications from trusted manufacturers such as Bürkert. Our stock includes:

✅ Direct-acting solenoid valves

✅ Servo-assisted models

✅ Valves suitable for water, oil, gas, refrigerants, and neutral media

Whether you’re designing a new system or replacing a valve in an existing installation, our technical team can help you specify the right product for your operational needs.

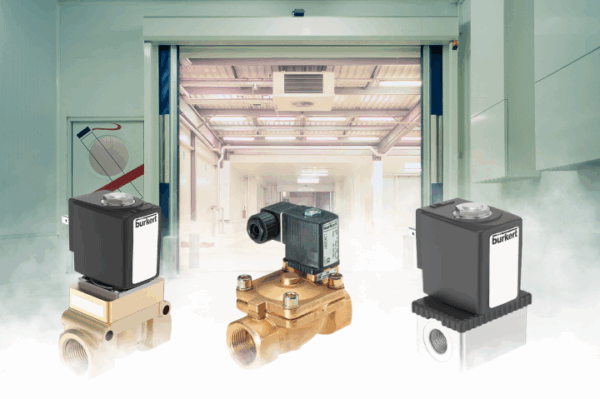

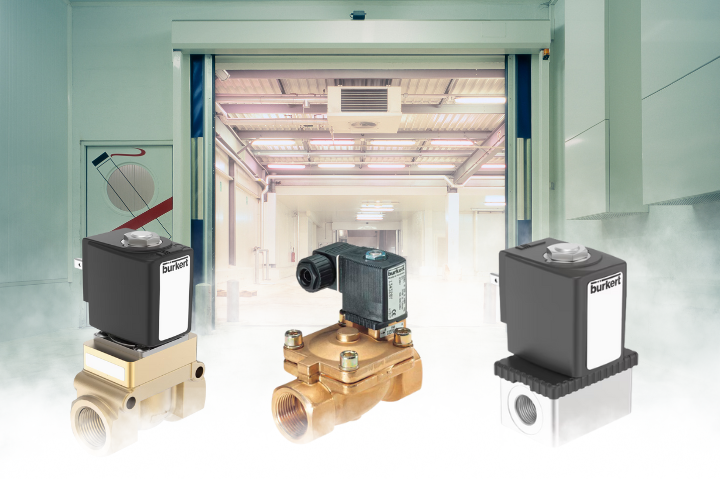

Recommended Bürkert Solenoid Valves for Refrigeration

BM Engineering Supplies offers a range of Bürkert solenoid valves suitable for refrigeration applications. Here are some options:

Bürkert Type 6013 – Direct-Acting 2/2 Way Solenoid Valve

Ideal for controlling refrigerant flow in small to medium systems, this valve offers reliable operation and is compatible with various refrigerants.Bürkert Type 5404 – Servo-Assisted 2/2 Way Solenoid Valve

Suitable for larger refrigeration systems, this valve handles higher flow rates and operates efficiently under varying pressures.Bürkert Type 5281 – Servo-Assisted 2/2 Way Solenoid Valve

Designed for general-purpose applications, including refrigeration, this valve offers versatility and dependable performance.

These valves are constructed with materials compatible with common refrigerants and are designed to withstand the demands of refrigeration systems.

Get Expert Support

With decades of experience supplying valve solutions to the HVAC-R industry, BM Engineering is your trusted partner for solenoids for refrigeration. Our engineers offer expert guidance to ensure reliable, efficient, and compliant systems.

📞 Call us on 0141 762 0657 or 📩 email sales@bmengineering.co.uk to discuss your project requirements.