Optimising Industrial Refrigeration Systems with the Right Valves

Optimising Industrial Refrigeration Systems with the Right Valves

Industrial refrigeration is essential in industries such as food and beverage processing, pharmaceutical manufacturing, and cold storage, where precise temperature control, energy efficiency, and safety are vital. Selecting the appropriate industrial refrigeration valves can significantly enhance performance, reduce refrigerant leakage, and lower operational costs. In this guide, we explore how BM Engineering Supplies offers reliable, high-quality solutions to optimise your refrigeration system.

Why Valves Are Essential in Industrial Refrigeration

Valves regulate refrigerant flow, control system pressure, and ensure safety. Choosing the wrong valve – or failing to upgrade ageing systems – can result in:

- Refrigerant leaks pose safety and environmental risks.

- Temperature inconsistencies can compromise product quality.

- Excessive energy use leads to high operational costs.

- Poor condensate or wastewater management risks hygiene and compliance issues.

Explore our full valve product range for tailored refrigeration system solutions.

Key Valve Types for Industrial Refrigeration Systems

Cryogenic Valves for Ultra-Low Temperatures

For refrigeration applications involving liquefied gases like CO₂, nitrogen or LNG, cryogenic valves are essential. These valves maintain reliable performance at temperatures as low as -196°C.

-

- Extended bonnets to protect seals from freezing.

- Robust materials, typically stainless steel and Low-temperature carbon steel (LTCS) valves, to prevent brittleness and leaks. e.g. ASTM A350 LF2

- Assembled and tested in cryogenic conditions to meet stringent quality and safety standards.

While BM Engineering does not currently list cryogenic valves as a standalone product, we offer high-performance stainless steel butterfly valves and ball valves that meet many industrial refrigeration needs.

Ball Valves for Industrial Refrigeration

Ball valves are ideal for isolating and controlling refrigerant flow with minimal leakage. At BM Engineering Supplies, we stock a full range of:

- Trunnion Ball Valves – Ideal for high-pressure systems, offering secure shut-off and improved safety.

- Floating Ball Valves – Designed for medium-pressure refrigeration systems, ensuring consistent sealing and smooth operation.

Butterfly Valves in Industrial Refrigeration Applications

Butterfly valves are commonly used in large-capacity or glycol-based refrigeration systems. BM Engineering offers:

- Wafer Butterfly Valves – A space-saving option for plant rooms with limited installation clearance.

- Lugged Butterfly Valves – Suitable for applications needing frequent maintenance access and positive shut-off.

Temperature Gauges for Accurate Monitoring

Maintaining temperature visibility is crucial. BM Engineering Supplies offers:

- Bimetallic Temperature Gauges – Durable, reliable gauges that operate without electricity.

Why ASTM Matters in Industrial Refrigeration Valves.

When it comes to industrial refrigeration, the choice of materials is as important as the valve design itself. At BM Engineering Supplies, we prioritise materials that meet or exceed ASTM (American Society for Testing and Materials) standards to ensure durability, compliance, and safety.

Our refrigeration valves are commonly manufactured using ASTM A351 CF8M stainless steel, which offers superior corrosion resistance and mechanical performance at both ambient and sub-zero temperatures. This makes it ideal for applications involving refrigerants like CO₂, ammonia, and glycol-based coolants.

Benefits of ASTM-Compliant Materials in Refrigeration Systems:

- Corrosion resistance – Critical in environments with chemical refrigerants or moisture buildup.

- Temperature tolerance – Maintains structural integrity in cryogenic and high-pressure systems.

- Mechanical strength – Reduces the risk of cracks, leaks, or failure under stress.

- International compliance – Ensures compatibility with global food, pharma, and industrial standards.

Many of our stainless steel valves, ball valves, and butterfly valves are constructed from ASTM-grade materials to guarantee longevity and performance in demanding refrigeration environments.

BM Engineering Refrigeration Valve Solutions

We provide a full selection of refrigeration-suitable valves and components:

- Flow Control Valves – Maintain consistent refrigerant or glycol flow and regulate pressure.

- Shut-Off Valves – Used to isolate system sections quickly and safely for maintenance.

- Drainage Valves – Assist with condensate removal and system defrost cycles.

- Pneumatic Actuators – Improve system automation and reduce manual intervention.

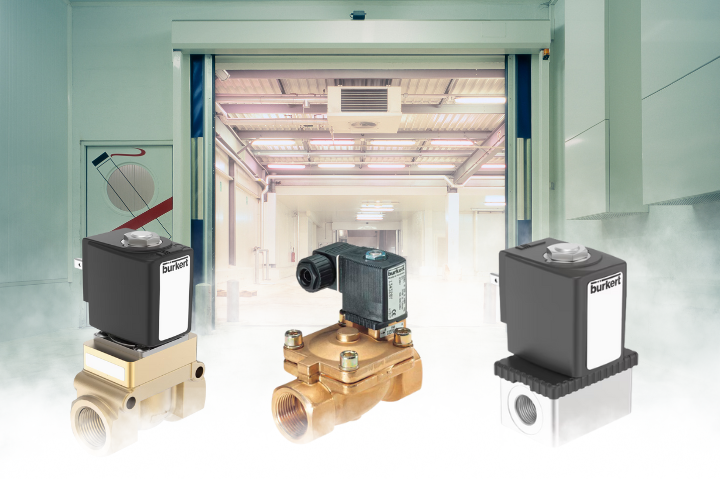

- Solenoid Valves – Fast-acting and reliable, perfect for automated refrigerant control.

Looking for assistance with selection or installation? Speak to our team via our contact page.

Case Study: Refrigeration System Upgrade Success

A UK-based food processing plant partnered with BM Engineering Supplies to overhaul its ageing industrial refrigeration infrastructure.

Solution Highlights:

- Installed trunnion ball valves with cryogenic extensions for improved refrigerant control.

- Integrated pneumatic actuators for remote operation and reduced downtime.

- Added temperature gauges for real-time monitoring.

Results:

- 40% improvement in energy efficiency.

- 100% elimination of refrigerant leaks with certified shut-off valves.

- 30% reduction in maintenance time due to better access and automation.

- Improved condensate management, aiding compliance with food industry hygiene standards.

Read more success stories on our case studies page.

Conclusion

Selecting the right valves for industrial refrigeration systems is crucial for achieving energy efficiency, reliable operation, and cost savings. BM Engineering Supplies offers a diverse range of high-performance refrigeration valves, ensuring optimised system performance for various industries.

For expert advice on upgrading your industrial refrigeration system, visit www.bmengineering.co.uk/contact-us and explore our top-quality refrigeration valve solutions.

Visit our online store at www.bmengineering.com/store

Or contact BM Engineering Supplies today

at 0141 762 0657 or via email at sales@bmengieering.co.uk.