What is the difference between a valve and an actuator?

When it comes to industrial valves and their accessories, they can seem complex to discern at first glance. However, they are simple to discern with a little more insight. To help you better understand the difference between an actuator and a valve, we at BM Engineering have put together this convenient guide to help you understand more clearly what their main features and functions are and how they are used in industrial applications.

What is a valve?

With regard to industrial applications, a valve is a device used to regulate, control and stop the flow of fluid or matter through a pipe or passage. A valve typically consists of a movable element, such as a disc or a plug, that can be opened, closed, or adjusted to control the flow rate. How a valve regulates the flow is what differentiates the various types of valves that you can find, each ideal for different applications.

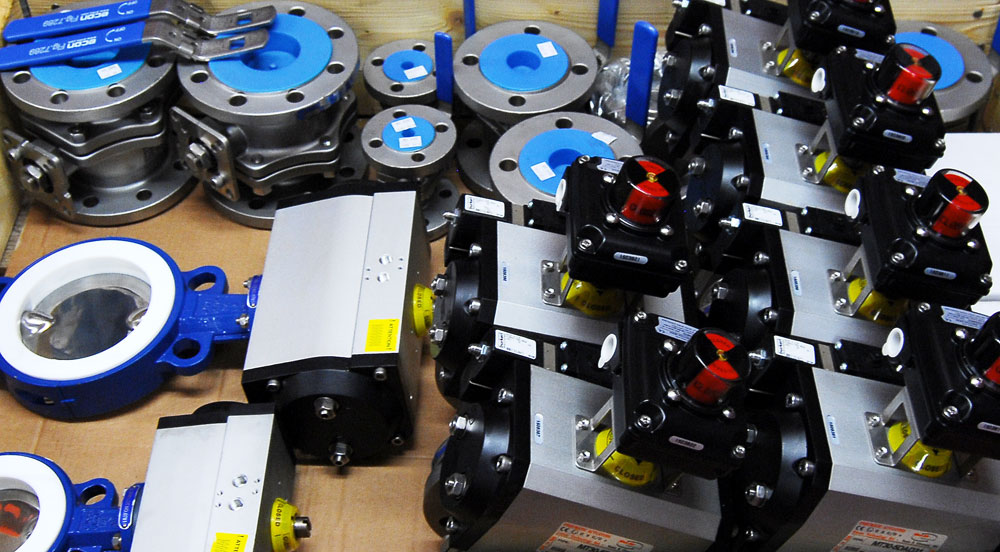

Due to their versatility and universal practicality, valves are used across a vast range of industries. Valves can be seen to be used in distillation, the food industry, pharmaceuticals and more, with certain types of valves being best suited for some of these specifically. Just some of the types of industrial valves that are used include ball valves, gate valves, butterfly gate valves and globe valves.

The types of valve

There are various types of valves that are ideal for separate functions. Below is some additional information as to how the above-mentioned types of valves function and their distinctive properties:

- Gate valves: These valves have a sliding gate-like disc that moves up and down to either completely block or allow fluid flow. They are typically used in applications that require full flow or shut-off conditions.

- Ball valves: Ball valves have a rotating ball with a hole through the centre. When the ball’s hole aligns with the pipe, the valve is open, and when the ball is rotated to block the flow, the valve is closed.

- Butterfly valves: These valves have a disc-shaped closure element, known as a butterfly disc, which rotates at a right angle to the flow path. When the disc is parallel to the flow, the valve is open, and when it is perpendicular, the valve is closed.

- Globe valves: Globe valves have a movable plug (disk) that can be raised or lowered onto a stationary ring seat to regulate the flow. They are commonly used for throttling and controlling the flow rate.

What is an actuator?

Holistically, an actuator is a mechanism or device used to convert an input signal into a physical motion or force. So in the context of valves, actuators are used to automate their operation within an application without the need for human input. Therefore, the difference between a valve and an actuator is that the valve operates the flow of media while the actuator automatically controls its function. In this manner, an actuator could be considered as an accessory to the valve.

An actuator functions by receiving a control signal, which will often be in the form of electrical, pneumatic or hydraulic input, and translating it into a mechanical motion that opens, closes or adjusts the valve position.

The types of actuator

The differences between the types of actuators are down to what type of signal the actuator receives to control a valve. Below is some further information on the distinctive qualities of each type of actuator:

- Electric actuators: These actuators use electrical power to generate motion. They can be operated through various control signals, such as analogue signals (e.g., 4-20 mA) or digital signals (e.g., on/off signals). Electric actuators are commonly used in applications that require precise control and automation.

- Pneumatic actuators: Pneumatic actuators use compressed air or gas to create the necessary force for valve operation. They are often used in industrial applications due to their reliability, simplicity and fast response time.

- Hydraulic actuators: Hydraulic actuators use pressurised hydraulic fluid to generate the force required for valve operation. They offer high-force capabilities and are commonly used in heavy-duty applications or systems that require high precision and control.

The difference between an actuator and a valve

In summary, valves and actuators often function very closely within process applications but have distinct purposes that differentiate them.

The difference between a valve and an actuator is that a valve is the primary device that controls the flow of fluid or matter within a process, while an actuator is an additional component that provides the necessary mechanical force or motion to operate the valve automatically. The actuator can be considered the “motor” that operates a valve opening or closing.

Actuators and valves at BM Engineering

We hope you now better understand the difference between an actuator and a valve. Though initially seeming similar, you can now see that there’s a distinction between the two and each serves their separate functions.

In addition to all of the industrial valves mentioned above as part of our extensive collection, we also stock an array of electrically and pneumatically operated actuators. These include our Max Air MT/UT series and Kinetrol actuators which are built for performance and to stand the test of time.

If you need further assistance regarding your requirements for a valve or an actuator, don’t hesitate to contact us today at 0141 762 0657, or email us at sales@bmengineering.co.uk