Ensuring Optimal Performance: The Importance of Air Quality in Pneumatic Systems

In industrial applications, pneumatic systems are integral for automation, material handling, and process control. However, the efficiency and longevity of these systems are heavily influenced by the quality of the compressed air supplied. Contaminants such as moisture, oil, and particulates can compromise system performance, leading to increased maintenance costs and potential downtime.

Understanding the Impact of Contaminated Air on Pneumatic Systems

Compressed air often contains impurities that, if not properly managed, can adversely affect pneumatic systems:

-

Moisture: Water vapour can condense within the system, leading to corrosion of metal components and degradation of seals and lubricants.

-

Oil: Oil aerosols can contaminate sensitive components, impairing their function and potentially violating industry cleanliness standards.

-

Particulates: Dust and debris can cause abrasion, leading to premature wear of valves, cylinders, and other critical components.

Implementing effective air preparation solutions is essential to mitigate these risks and ensure the reliable operation of pneumatic systems.

Best Practices for Maintaining Air Quality in Pneumatic Systems

To maintain optimal air quality and, consequently, the efficiency of pneumatic systems, consider the following practices:

1. Regular Maintenance of Air Preparation Units

Air preparation units, including filters, regulators, and lubricators (FRLs), should be inspected and maintained regularly. This includes checking for blockages, replacing filter elements, and ensuring proper lubrication levels.

2. Implementing Drying Solutions

In environments where moisture is prevalent, incorporating air dryers can effectively remove water vapour, preventing condensation and corrosion within the system.

3. Utilising High-Quality Filtration

Employing high-efficiency particulate air (HEPA) filters can capture fine particulates, ensuring that only clean air enters sensitive components of the pneumatic system.

4. Monitoring and Controlling Oil Levels

While some pneumatic systems require lubrication, excessive oil can lead to contamination. Utilising oil mist separators and ensuring proper oil levels can maintain system cleanliness.

BM Engineering’s Solutions for Air Quality Management

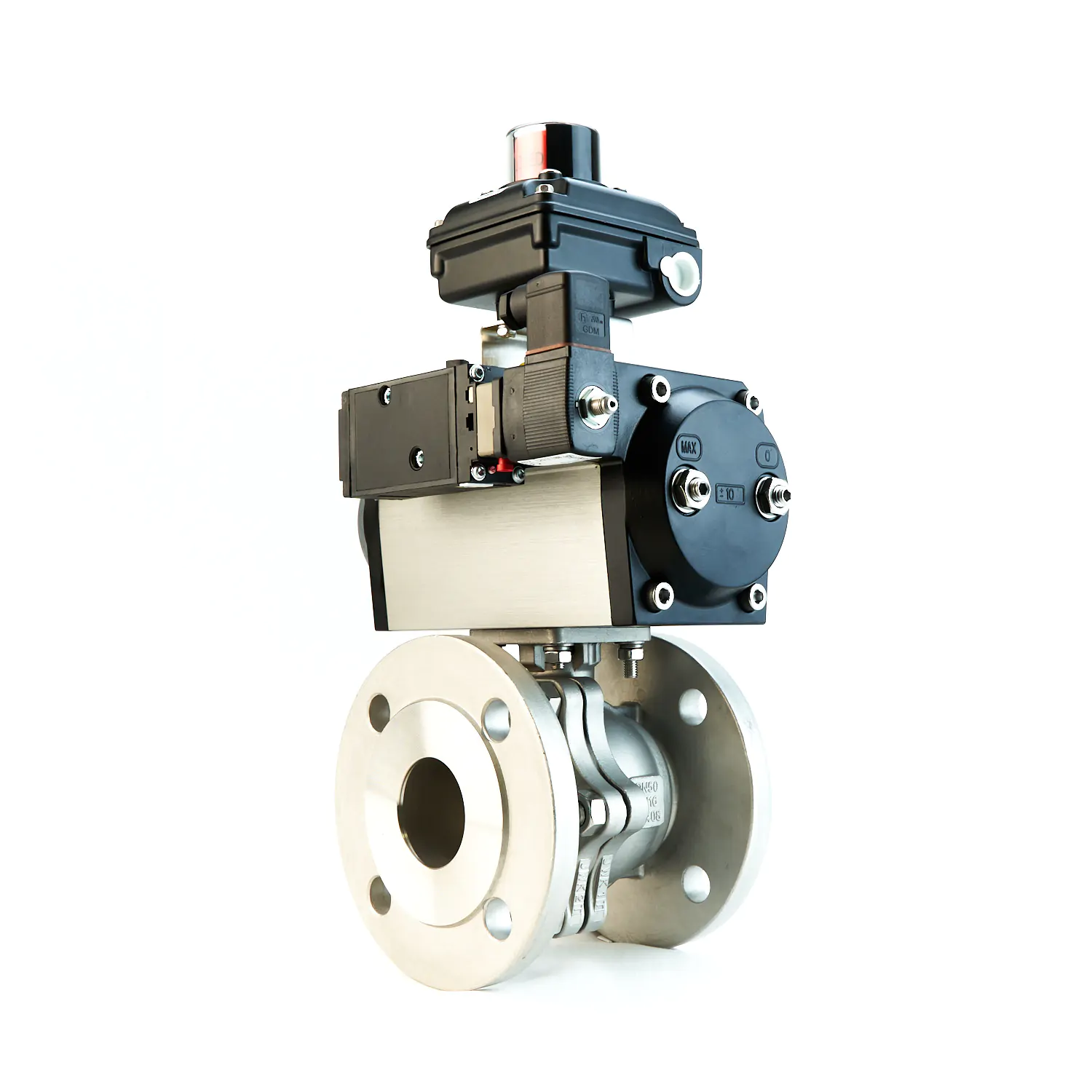

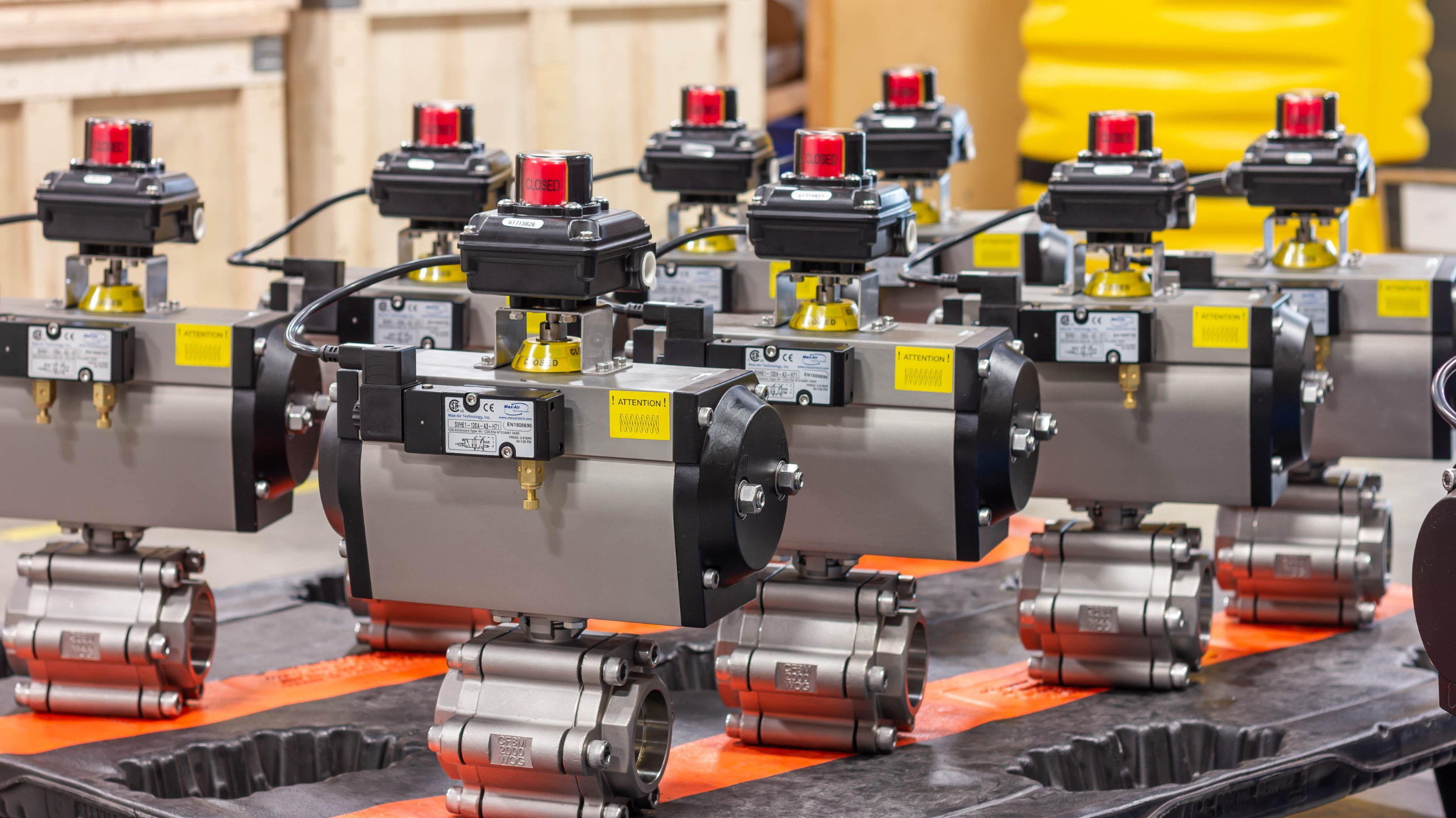

At BM Engineering, we offer a range of products designed to enhance the air quality in your pneumatic systems:

-

Air Preparation Units: Our FRL units are designed to filter, regulate, and lubricate compressed air, ensuring optimal performance.

-

Air Dryers: We provide desiccant and refrigerated air dryers that effectively remove moisture from compressed air systems.

-

High-Efficiency Filters: Our HEPA filters are capable of capturing fine particulates, maintaining the cleanliness of your pneumatic components.

By integrating these solutions, you can significantly improve the air quality in your pneumatic systems, leading to enhanced performance and reduced maintenance costs.

Conclusion

Maintaining high air quality is paramount for the efficient operation of pneumatic systems. By implementing regular maintenance practices and utilising quality air preparation equipment, you can ensure the longevity and reliability of your systems. Explore our range of products at BM Engineering to find the right solutions for your pneumatic needs.

Stay Connected

Follow BM Engineering on LinkedIn

Watch product insights on YouTube